服务热线:00852-30780812

Fahrenheit Particle Size Basics.

The basic Fahrenheit particle size test method is the steady flow through air method, where the specific surface area and average particle size are determined under constant air flow and pressure conditions.

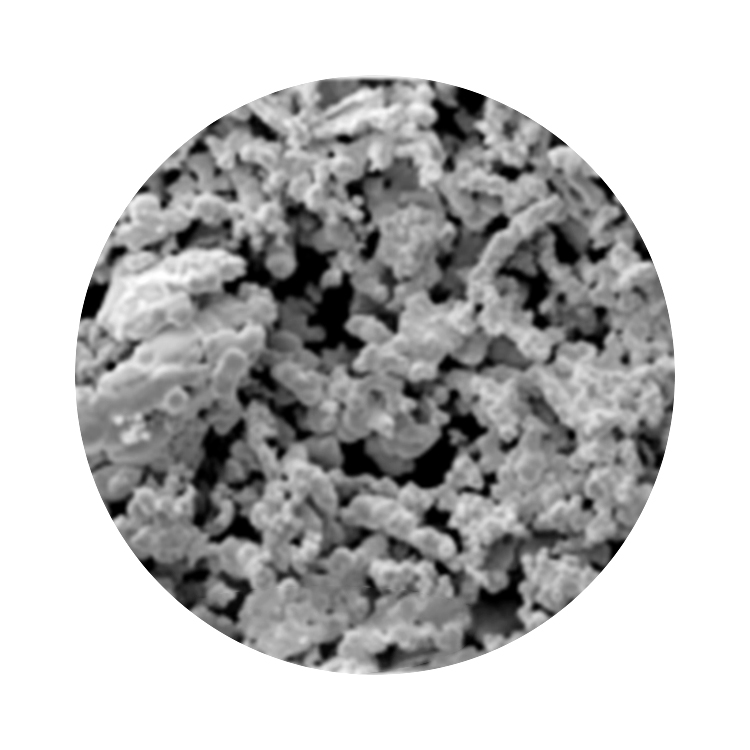

This method is representative and reproducible due to the large number of samples taken. For more regular powders, the results are consistent with those obtained by microscopy. When used in conjunction with the BET method (BET), which reacts to the full specific surface and size of the primary particles, it is possible to determine the degree of aggregation of the powder and to determine the number of primary particles in the secondary particles.

Description of the Fahrenheit particle size method

The Fahrenheit method is a relative measurement method that cannot accurately determine the true particle size of a powder and is only used to control the process and the quality of the product. It is only able to accurately measure the passage rate of air through a powder accumulation, the size of which depends on its pore structure. The porosity, particle shape, particle size, particle size composition, particle size distribution and pressing method of the powder accumulation all influence the pore structure. Therefore, the method is only applicable to powders with the same chemical composition and similar particle size composition. For powders with the same chemical composition but different particle size composition, larger measurement errors occur. Sometimes two powders with the same chemical composition but different particle size composition will give the same Fickian value because they have the same throughput. Therefore, the particle size values measured by this method cannot be compared with other particle size measurements.

The specific measurement procedure for powder particle size is described in GB/T 3249-2009 Method for the determination of the Fickian size of metals and their compounds. Each instrument is equipped with a ruby standard tube with a high and low value for the specified porosity. The higher values are used for the determination of finer powders, i.e. in the range 0.20-20 μm, while the lower values are used for the determination of coarser powders, i.e. in the range 20-50 μm.